Dye-Sublimation is a printing method used on a variety of surfaces, such as polyester textiles and specially coated ceramics and metals.

The dye-sublimation process is fairly straightforward. There are three key factors: sublimation ink, heat, and pressure. The water-based ink is first printed on special heat-resistant sublimation transfer paper in reverse using large format inkjet printers. On textiles, it is then transferred onto polyester fabric in a heat press operating in high temperature (around 400 degrees Fahrenheit). The heat opens up the pores of fabric and the combination of high heat and pressure turns the dye from a solid state into a gas without becoming a liquid state. The dye in gas form permeates the fabric before solidifying in the fibres of the material when the fabric is removed from the heat press, and the pores also close as a result of a drop in temperature to seal the print.

If you are looking to print bold, vibrant, and durable graphics on items like sportswear, fashion apparel, mouse pads, snowboards, and other select hard surface items, sublimation may be the answer!

Dye-sublimation printing is much more eco-friendly compared to other printing methods that use solvents and additional chemicals to prepare the fabric for printing. The sublimation inks are water-soluble and dye-based, but they still have chemicals and will be disposed in compliance to government regulations. In general, there is very little waste and sublimation transfer paper and tissue paper are always recycled.

Dye-sublimation and screen-printing both works on polyester materials. However, dye-sublimation will not affect the feeling of the material and generally yields a better result for printing on sportswear apparel and home furnishing goods. The colours are vibrant, do not wash out, and the process is neither as complicated nor messy as screen-printing. Dye-sublimation is also more cost-effective because it is quicker and easier to set-up, and short-runs are fairly affordable.

Screen-printing uses plastisol ink, which can be heavy (affecting the breathability of the garment) and is prone to cracking when the printed material is stretched or worn over time. Furthermore, it may use additional chemicals to prime the fabric for printing. However, one advantage of screen-printing is that it can print almost any colour (including white) on any garment colour. Sublimation only prints in CYMK, which excludes white.

In the end, it comes down to personal preference, what the sublimated item is used for, and how it is used.

Sublimated prints are permanent and extremely durable. The reason being that once the ink is fused within the fabric, the print cannot be scratched or washed off, nor would it crack or peel. Most fabrics can be laundered many times without noticeable loss in print quality, although dye-sub printed fabric should not be dry-cleaned. Long-term exposure over many years under the sunlight will cause the print to fade, but these conditions only applies to signage and flags. All in all, polyester fabrics are extremely versatile and used in many applications. On hard surface objects, sublimation prints out beautifully on smooth surfaces, but not resistant to scratches and scrapes.

Dye-Sublimation is a great printing method on a variety of surfaces, such as polyester textiles (comprising of at least 65%, but ideally at least 80% polyester) and specially coated ceramics. Polyester textile materials can be knitted or woven, including stretch knits, poplins, sheers, meshes, poly silks, canvases, and more.

Sublimation ink only bonds on polyester/polymer coated material, so cotton material will not work. Certain mixes of poly-cotton may work, although we would recommend screen-printing or even direct-to-garment printing instead.

Microfibre towels, synthetic silk, and synthetic satin work perfectly with dye-sublimation. Natural silk can be sublimated but the print will look faded (great for subtle/vintage effect) and may wash out slightly. Nylon must be sublimated at a lower temperature, but the vibrancy and longevity should not be affected.

The limitation of spot sublimating on premade garments depends on the design and the garment itself. For example, it will be difficult to perfectly print a graphic that crosses over seams or wraps around a large area of the body (and vice versa). There is a higher chance of creasing during heat pressing, particularly around the seams, in which the print will be missed. We recommended restricting the size and avoiding seams for spot sublimation.

Although sublimation is considered permanent, it is still reactive. It is important to wash sublimated items in cold water on delicate cycle or hand wash, use gentle detergents, and tumble-dry low (or line dry away from direct sunlight). Industrial wash and dry-cleaning may ruin the print, as well as hot water, bleach, and other harsh chemicals.

Sublimation printers can only print CYMK, which excludes white ink. Also, sublimation ink does not transfer well on dark materials since it is not truly ink, but a semi-transparent dye. Because of this, the print is generally hard to see against a dark fabric as the colour of the fabric affects how the print looks like in the end. Same idea goes for printing on coloured paper. The lighter the colour of the fabric, the better the print result will be.

The usual temperature used in the industry is 400 degrees Fahrenheit, but it is dependent on the material and dwell time required (longer dwell time = lower temperature). Some materials also have a lower melting point and will need the temperature reduced.

Sublimation does not require a high amount of pressure for most substrates, but determining a dwell time is a matter of testing and practicing to see what works best.

The length of time it takes to sublimate a material depends on the composition and nature of the fabric or polyester coating. There is a recommended dwell time for each substrate when it enters the heat press. The harder the coating, the longer it will take a sublimate. Factors such as the heat press equipment, ink saturation, and paper types can affect the sublimation time as well.

Actual production (turnaround) time depends on your project scope, but it is typically a week. The more information we know, the more accurate we can estimate the turnaround time for you.

If you need your printing rushed within 24 hours, there will be a 10% rush fee.

There is currently no set-up fee for roll-to-roll/panel/paper sublimation printing. The only catch is that we require the artwork to be print ready (please review the file specifications in FAQ).

Our cost is based on:

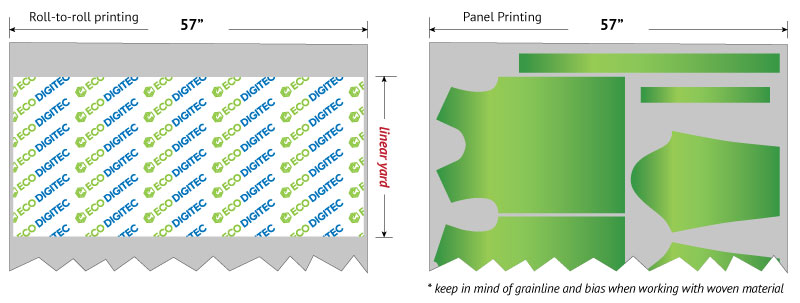

- linear yard for roll-to-roll/panel printing

- print size and quantity of prints for spot sublimation printing

- whether or not we are providing the fabric

- whether or not we are sublimating the fabric/goods (yes, we also sell printed sublimation paper too!)

- whether the roll of fabric you provide needs to be preshrunk

Please contact us for a quote!

Not really. Only 1 yard is required for roll-to-roll/panel sublimation printing and sublimation paper printing. For promotional items, please refer to our price-list for specific minimums.

Don’t forget, you can get a complimentary 7″ x 7″ sample print (up to three samples every 2 weeks)!

You are encouraged to bring your own fabric to save costs and have the freedom of selection from the offerings out there. If it is something we haven’t worked with before, please bring a sample in for us to test. Also important to note is that the widest roll of fabric that can pass through our large-format heat press is 63 inches wide (by however long).

We provide three types of fabrics: polyester poplin, polyester twill, and poly silk. These are used to print backdrops, tablecloths, retail displays, and outerwear.

The fabric we offer is already preshrunk, but it will still shrink a little bit (negligible) due to the high heat during pressing and after washing.

If you want to use your own fabric, we recommended bringing it in to test for shrinking as well as printing.

Please email us at info@ecodigitec.com with your artwork file. Please be aware that some email programs may embed and/or downsize your file (eg. JPEG, BMP, TIFF); what you can do is upload your file on a file-sharing website such as Dropbox or WeTransfer (especially if it is too large for an email attachment), and send us the download link.

It is important to include information such as what you are printing, how many rolls/yards/garments, which design, and if you have a shipping date. We can help you better the more we know!

We accept AI, PSD, EPS, PDF, JPEG, BMP, PNG, TIF files.

For repeating seamless patterns, please prepare the file as a JPEG, BMP, or TIF file and make sure your file’s colour profile is in CMYK for CMYK printing.

Please keep the file under 200MB if possible!

To prepare artwork for printing, the artwork first needs to be in high-resolution or vector format for better print quality. 150-300 ppi (pixels per inch) is recommended. The file can become rather large, so please reserve high ppi images for objects viewed up close. Banner/flags can afford to be lower ppi (around 150).

It is important to create/set images at actual print size because resizing the image later may diminish the image quality (extra pixels are added to raster graphics). Vector images are ideal because they are based on mathematical calculations in terms of points, lines, and curves, and can be resized without loss of image quality.

Please keep the file under 200MB if possible!

Close, but not very likely to be exact. There are too many factors involved, such as: media type, colour range/settings, shifting.

Media type – If your artwork was created on paper/canvas and was later photographed or scanned for digital printing, the camera/scanner/monitor/lighting output is already affecting your artwork. Same goes for artwork created on computers; What you see on a digital screen is hard to reproduce exactly on a different medium. Furthermore, printing on paper and printing on fabric results in different outputs because of surface, material, and printing variations.

Colour range/settings – Inks and printers have a range of colours they can output, which is also known as the colour gamut. Like how there are some colours that are out of the colour gamut on your monitor, there are some out of the printers’ range as well. Therefore, colours out of gamut on the printer will be printed to the closest colour it can produce.

Shifting – When the fabric shifts, the print will look like it has a slight shadow, more evident on areas with darker colours. We try our best to prevent it, but it is a natural printing variation.

To ensure that the colours print as close as possible, please make sure your file’s colour profile is in CMYK for CMYK printing and have a sample printed first. We also recommend printing a colour chart so you can easily use it as a guide to predict final appromixate colour output on a particular fabric.

No. We only access your print files when we need to print your order. If we would like to photograph your product to use as promotional graphics, we will ask for your permission beforehand.

Most definitely! Please let us know ahead of time so we can allocate space for you.

We will gladly affix any waybills you send our way for your shipment. Otherwise, if you have an account with a specific courier, let us know your account number, shipping destination, preferred service to use, and leave the rest to us! Alternatively, we can also arrange shipping on our end and simply add the shipping charges to your invoice.

You can request for a 7″ x 7″ sample of one of the custom patterns we offer on our site, using our fabric or your own fabric. You can also print a 7″ x 7″ sample image of your own design. All free of charge, including nation-wide shipping. Limited to three samples for each customer every two weeks.

* We also recommend clients to print colour charts on a yard of fabric to use as reference. This is particularly handy to predict final approximate colour output on a particular fabric.